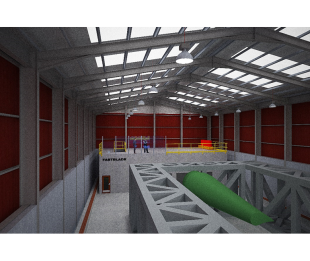

In 2017, School of Engineering researchers at The University of Edinburgh, led by Principal Investigator, Professor Conchúr Ó Brádaigh successfully applied for £1.8M funding from the Engineering & Physical Sciences Research Council (EPSRC) for the development of a Structural Composites Research Facility, aimed primarily at accelerated lifetime testing of composite tidal turbine blades. Since the project’s conception, the tidal energy sector has successfully grown and now requires a facility capable of testing larger and stiffer blades than anticipated. Since 2018, the University of Edinburgh have been working with Babcock Marine Limited to develop the FASTBLADE facility at the Rosyth Dockyard in Fife. The University Court of The University of Edinburgh approved the development of FASTBLADE on the Rosyth site in November 2019.

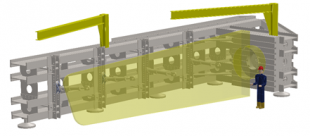

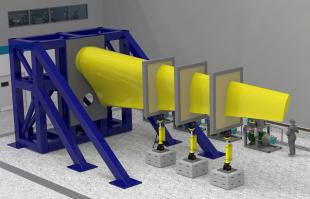

The innovative Structural Composites Research Facility (SCRF) was developed for faster fatigue or cyclic load testing of large structures. This will initially be focussed on fibre-reinforced composite material structures, such as stiff tidal turbine blades (e.g. fabricated from carbon fibre and glass fibre reinforced polymer resins).

The facility will be the first of its kind in the world, and will use a brand new, ultra-efficient digital displacement regenerative pumping hydraulic system. For fatigue testing of tidal turbine blades, the novel hydraulic actuation system will only use 25% of the energy input required by conventional hydraulic testing systems, and will test structures 8 times faster than possible with existing hydraulic systems (test frequency increase from 0.1 Hz to 1 Hz). This will enable more and faster impact-led academic research into fundamental engineering options for new materials technology and accelerated evaluation of tidal turbine blades leading to more rapid certification and deployment to market. Such a capability is critical to the success of this emerging composite materials technology for renewable energy and will accelerate the conversion of available tidal marine energy, which is currently under-exploited at a time of increasing national demand for energy.

Nationally, the facility will also underpin fundamental research in composite materials across all sectors, to be targeted at applications in high value manufacturing sectors such as aerospace, automotive, and civil engineering applications (e.g. structural health monitoring in bridges and buildings subject to ongoing fatigue under cyclic loading). Academics will benefit by access to a state-of-the art accelerated fatigue testing facility, opening new research opportunities on fundamental materials and process topics.

Industry will benefit by reduced design risk from better testing data and by reduction of product testing time, within the product development cycle times needed in the renewable energy, aerospace, naval defence, marine and infrastructure sectors.

Original animated simulation of the FASTBLADE Structural Composites Research Facility.