This project proposes to investigate the way the polymeric powders of different shapes and sizes flow, interact and sinter in the Laser Sintering process, through modelling and experimental validation. Laser sintering is part of the additive manufacturing technology, known for its benefits in industries where custom made products, lightweight and complex designs are required.

In laser sintering a polymer powder bed is heated to just below its melt temperature. A laser is then focused onto the bed which scans a raster pattern of a single layer of the final part. The bed lowers slightly and a new layer of powder is applied. The process is then repeated until the component is made and the additive layer process is complete.

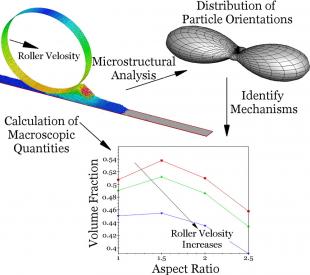

The spreading and compaction of the powder is an important part of the LS process, a non-uniform layer of powder leads to high porosity and weaker bonding between layers and therefore a structure with poor mechanical performance. Similarly, the size and shape of particles can change the sintering process. Larger contact areas between particles lead to a good sintering profile and ultimately to a high density part and good mechanical properties. Surface area of particles, polymer viscosity and surface tension are characteristics which will be considered when modelling the flow and sintering process.

Principal Investigator:

Postgraduate Researchers:

Dr. Sina Haeri