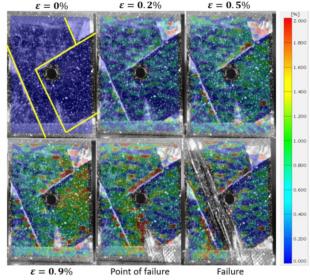

This project aims to develop novel recycled composites based on prepreg scrap. The prepreg scrap can be cut in short strands that can be distributed over the mould surfaces with different orientation. Different manufacturing processes have been analysed and the equivalent mechanical properties have been compared against the performance of equivalent quasi-isotropic continuous carbon fibre laminates. The influence of defects such as discontinuous tow ends, fibre curvature and resin pockets have been analysed by high-speed imaging and Digital Image Correlation.

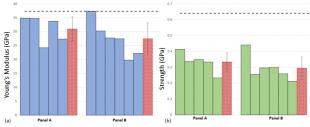

This manufacturing method has an inherently low cost and suits the specifications of sectors such as the automotive industry. It provides a random fibre distribution with equivalent stiffness to those of conventional quasi-isotropic panels, but half the strength. Still, the mechanical properties are superior in specific terms to those of aluminium and steel alloys. This methodology also provides notch-insensitive laminates, reducing the safety factors of components including metallic inserts for future assembly operations.

References.

[1] A. B. Ibrahim. Manufacturing and testing of randomly oriented strand board composites from scrap prepreg. MEng dissertation. The University of Edinburgh. 2020

Collaborators: University Carlos III Madrid

Funding: The Royal Society. RGS\R2\180091

Principal Investigator:

Francisca Martinez Hergueta

Postgraduate Researchers:

Afif Bin Ibrahim,

Rutger Kok