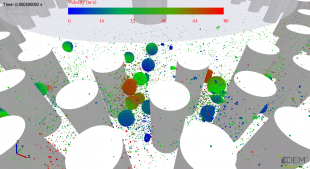

Population balance modelling (PBM) has been extensively used in system-scale simulations to track the size distribution of particles during aggregation and breakage processes [2]. The aim of this project is to perform multi-scale analysis of micro-scale DEM simulation results to inform the predictions of PBM at system scale. In this project, a bonded particle model based on the Timoshenko beam theory [3] was used to study a material’s grindability at single particle scale. At mill scale, DEM simulations were performed to obtain the impact velocity distributions under varying operational conditions. At process scale, PBM with a mechanistic kernel was used to predict the milling product size distribution. The DEM–PBM multi-scale coupling strategy has been shown to be a promising way to predict the performance of a milling process.

References

[1]N.S. Weerasekara, M.S. Powell, P.W. Cleary, L.M. Tavares, M. Evertsson, R.D. Morrison, J. Quist, and R.M. Carvalho. The contribution of DEM to the science of comminution. Powder Technology, 248:3 – 24, 2013. Discrete Element Modelling.

[2]J.A Herbst and D.W Fuerstenau. Scale-up procedure for continuous grinding mill design using population balance models. International Journal of Mineral Processing, 7(1):1 – 31, 1980.

[3]N. J. Brown, J. F. Chen, and J. Y. Ooi. A bond model for DEM simulation of cementitious materials and deformable structures. Granular Matter, 16(3):299 – 311, 6 2014.