Mechanical Engineering

The design of all chemical process starts from mathematical modelling and computational thermodynamics. The reliability of a thermodynamic model in predicting or correlating phase equilibria depends strongly on the value its parameters. Carefully evaluated parameters enable a precise calculation of the phase equilibria and of the process units, affecting as a consequence the costs of a chemical process.

In several cases, the thermodynamic parameters commonly used in process simulators are wrong. They do not return a comprehensively right equilibrium.

The project focuses on the development of an open tool for the correct regression and correlation of thermodynamic data in robust mathematical models. The project involves the development and use of optimization techniques. Special modelling, including Bayesian regression or similar techniques, will be also used.

In this project, you will design digital open and user-friendly tools that can easily integrate with existing process simulators (e.g. AspenPlus, Unisim) and exploit recent advanced algorithms [1, 2]. The ambition of this project is to earn the sector’s support and enable the widespread use of the tool in place of the current unreliable counterparts.

You will work in the Emerging Sustainable Technologies Laboratory (ESTech Lab) [3], be part of a world leading research group in sustainable technologies towards the development of the first robust tool for thermodynamic model identification and calibration, have access to state-of-the-art computing facilities and brainstorm new digital tools across all thermodynamic problems.

Your studies will be carried out at the Institute for Materials and Processes (IMP) and could include occasional experiments to validate models. You will attain skills in modelling, design and testing of innovative digital tools.

Please note, the position will be filled once a suitable candidate has been identified.

[1] https://www.sciencedirect.com/science/article/pii/S037838121400226X

[2] https://www.sciencedirect.com/science/article/pii/S0378381220300297

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. As well as:

- Proficiency with Computational Thermodynamics of Fluid Phase Equilibria

- Proficiency with at least one coding tool and related graphical user interface

Further information on English language requirements for EU/Overseas applicants.

Desirable criteria:

- knowledge of optimization methods;

- knowledge of Bayesian regression.

A number of scholarships are available to competitive candidates. For more information on the funding application process, please contact the project’s supervisor or visit the School of Engineering website.

Applications are also welcomed from self-funded students.

The design of the forthcoming future is negative in emissions. Among the negative emission technologies options, those capturing CO2 directly from the air are called Direct Air Capture technologies. Direct Air Capture technologies are regarded as the solution having the biggest carbon removal potential but is also the least known. If Direct Air Capture had to be an essential measure, future society would deal with severe restrictions in energy availability [1].

However, using the captured atmospheric CO2 for conversion into chemicals and fuels has the right scale not to impinge in the energy system and attractive economic outlook.

In your studies you will work in the Emerging Sustainable Technologies Laboratory (ESTech Lab) [2], be part of a world leading research group in carbon capture towards the development of technological avenues for Direct Air Capture and Conversion into chemicals and fuels.

Your studies will be carried out at the Institute for Materials and Processes (IMP) and will include modelling activities. You will attain skills in modelling and design of new negative emission technologies and production paths.

Please note, the position will be filled once a suitable candidate has been identified.

[1] Santori et. al. Adsorption artificial tree for atmospheric carbon dioxide capture, purification and compression, Energy 162 (2018) 1158-1168. https://doi.org/10.1016/j.energy.2018.08.090

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. As well as:

- Proficiency with Computational Thermodynamics of Fluid Phase Equilibria

- Proficiency with at least one coding tool and related graphical user interface

Further information on English language requirements for EU/Overseas applicants.

Desirable criteria: knowledge of optimization methods.

A number of scholarships are available to competitive candidates. For more information on the funding application process, please contact the project’s supervisor or visit the School of Engineering website.

Applications are also welcomed from self-funded students.

Digital tools are omnipresent and their rise exponential. Cloud and digital services have improved our lives and, overall, reduced carbon emissions, although at the expense of a growing electricity demand from data centres. Remarkably, nearly half the data centre electricity input is for self-cooling, which provides an opportunity for a technology able to harness low-grade heat and turn it into cooling power. The co-location of energy in form of heat and water is an opportunity.

The project focuses on the mathematical modelling and optimization of a proof-of-principle heat-powered cooling process that reduces waste heat and greenhouse gas emissions and boosts return on investment, while meeting all the sustainability criteria.

Special modelling, including machine learning, and cost of manufacturing tools guide the development of an optimised heat-to-cold concept designed to break through current barriers to commercialisation.

In this project, you will design digital tools for an innovative technology that uses low temperature heat for the production of cold by exploiting recent discoveries in material science and engineering [1, 2]. The ambition of this project is to earn the sector’s support and enable the widespread use of heat-powered cooling in place of the current electricity-driven counterpart.

You will work in the Emerging Sustainable Technologies Laboratory (ESTech Lab) [3], be part of a world leading research group in sustainable technologies towards the development of a proof-of-concept super-efficient processes for heat-powered cooling, have access to state-of-the-art computing facilities and brainstorm new technological avenues for cooling.

Your studies will be carried out at the Institute for Materials and Processes (IMP) and could include occasional experiments to validate models. You will attain skills in modelling, design and testing of innovative technologies for cooling.

Please note, the position will be filled once a suitable candidate has been identified.

[1] https://onlinelibrary.wiley.com/doi/full/10.1002/ente.202300548

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. As well as:

- Proficiency with Labview or similar data acquisition and control

- Proficiency with dynamic identification methods

Further information on English language requirements for EU/Overseas applicants.

Desirable criteria:

- knowledge of thermodynamics of fluid phase equilibria or physical chemistry;

- knowledge of computational tool such as Matlab, Mathcad, Mathematica etc… with emphasis on graphical user interface design.

A number of scholarships are available to competitive candidates. For more information on the funding application process, please contact the project’s supervisor or visit the School of Engineering website.

Applications are also welcomed from self-funded students.

Digital tools are omnipresent and their rise exponential. Cloud and digital services have improved our lives and, overall, reduced carbon emissions, although at the expense of a growing electricity demand from data centres. Remarkably, nearly half the data centre electricity input is for self-cooling, which provides an opportunity for a technology able to harness low-grade heat and turn it into cooling power. The co-location of energy in form of heat and water is an opportunity.

The project focuses on the design and demonstration of a proof-of-principle 3D printed heat-powered cooling device that reduces waste heat and greenhouse gas emissions and boosts return on investment, while meeting all the sustainability criteria.

Special characterisation techniques and additive manufacturing tools guide the development of a geometrically-optimised heat-to-cold concept which is designed to break through current barriers to commercialisation.

In this project, you will research and develop an innovative technology that uses low temperature heat for the production of cold by exploiting recent discoveries in material science and engineering [1, 2]. The ambition of this project is to earn the sector’s support and enable the widespread use of heat-powered cooling in place of the current electricity-driven counterpart.

You will work in the Emerging Sustainable Technologies Laboratory (ESTech Lab) [3], be part of a world leading research group in sustainable technologies towards the development of a proof-of-concept super-efficient processes for heat-powered cooling, have access to state-of-the-art equipment including rapid prototyping tools and brainstorm new technological avenues for cooling.

Your studies will be carried out at the Institute for Materials and Processes (IMP) and will include modelling activities supported by experiments. You will attain skills in modelling, design and testing of innovative technologies for cooling.

Please note, the position will be filled once a suitable candidate has been identified.

[1] https://onlinelibrary.wiley.com/doi/full/10.1002/ente.202300548

[2] https://pubs.acs.org/doi/10.1021/acs.est.9b06037

[3] https://www.linkedin.com/in/giulio-santori-a365546/

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. As well as:

- Proficiency with plastic 3D printing, both FDM and Stereolithographic methods

- Familiarity with Labview or similar data acquisition and control

- Familiarity with dynamic identification methods

Further information on English language requirements for EU/Overseas applicants.

Desirable criteria:

- knowledge of thermodynamics of fluid phase equilibria or physical chemistry;

- proficiency in computational tool such as Matlab, Mathcad, Mathematica etc… with emphasis on graphical user interface design.

A number of scholarships are available to competitive candidates. For more information on the funding application process, please contact the project’s supervisor or visit the School of Engineering website.

Applications are also welcomed from self-funded students.

Climate change is already exacerbating water scarcity bringing uncertainty in the future of the water availability vs. abstraction (water stress), especially in delicate eco-systems. At the same time, industry highly relies on water. In most of the water-demanding industrial sectors high water demand is co-located with high energy demand (water-energy nexus), similarly to countries that benefit from high solar thermal energy (high energy availability) and at the same need water. The co-location of energy in form of heat and water is an opportunity.

In this project, you will research and develop advanced dynamic mathematical models of an innovative technology that uses low temperature heat for the production of water with different quality (from drinkable to industry and agriculture). The technology will be powered by ultralow energy and exploit the temperature differences available in nature: air, soil and natural water (e.g. lakes, seas, rivers).

You will work in the Emerging Sustainable Technologies Laboratory (ESTech Lab) [1], be part of a world leading research group in sustainable technologies towards the development of user-friendly (Graphical User Interface) advanced model for the characterization and prediction of the dynamic performance of heat-powered clean water production (e.g. desalination), have access to state-of-the-art computing facility and brainstorm new technological avenues for clean water production.

Your studies will be carried out at the Institute for Materials and Processes (IMP) and will include short experimental activities to validate your models. You will attain skills in modelling, design of innovative technologies for clean water.

Please note, the position will be filled once a suitable candidate has been identified.

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. As well as:

- Proficiency with identification of process dynamic techniques;

- proficiency in computational tool such as Matlab, Mathcad, Mathematica etc… with emphasis on graphical user interface design.

Further information on English language requirements for EU/Overseas applicants.

Desirable criteria: knowledge of computational thermodynamics of fluid phase equilibria or physical chemistry.

A number of scholarships are available to competitive candidates. For more information on the funding application process, please contact the project’s supervisor or visit the School of Engineering website.

Applications are also welcomed from self-funded students.

Climate change is already exacerbating water scarcity bringing uncertainty in the future of the water availability vs. abstraction (water stress), especially in delicate eco-systems. At the same time, industry highly relies on water. In most of the water-demanding industrial sectors high water demand is co-located with high energy demand (water-energy nexus), similarly to countries that benefit from high solar thermal energy (high energy availability) and at the same need water. The co-location of energy in form of heat and water is an opportunity.

In this project, you will research and develop an innovative technology that uses low temperature heat for the production of water with different quality (from drinkable to industry and agriculture) by exploiting recent discoveries in material science and engineering [1, 2]. The technology will be powered by ultralow energy and exploit the temperature differences available in nature: air, soil and natural water (e.g. lakes, seas, rivers).

You will work in the Emerging Sustainable Technologies Laboratory (ESTech Lab) [3], be part of a world leading research group in sustainable technologies towards the development of a proof-of-concept super-efficient processes for heat-powered clean water production (e.g. desalination), have access to state-of-the-art equipment including rapid prototyping tools and brainstorm new technological avenues for clean water production.

Your studies will be carried out at the Institute for Materials and Processes (IMP) and will include modelling activities supported by experiments. You will attain skills in modelling, design and testing of innovative technologies for clean water production.

Please note, the position will be filled once a suitable candidate has been identified.

[1] https://patentscope.wipo.int/search/en/detail.jsf?docId=WO2025003650&_cid=P20-MAL3RA-15255-1

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree.

- Proficiency with Labview or similar data acquisition and control

- Familiarity with dynamic identification methods

Further information on English language requirements for EU/Overseas applicants.

Desirable criteria:

- knowledge of thermodynamics of fluid phase equilibria or physical chemistry;

- proficiency in computational tool such as Matlab, Mathcad, Mathematica etc… with emphasis on graphical user interface design;

A number of scholarships are available to competitive candidates. For more information on the funding application process, please contact the project’s supervisor or visit the School of Engineering website.

Applications are also welcomed from self-funded students.

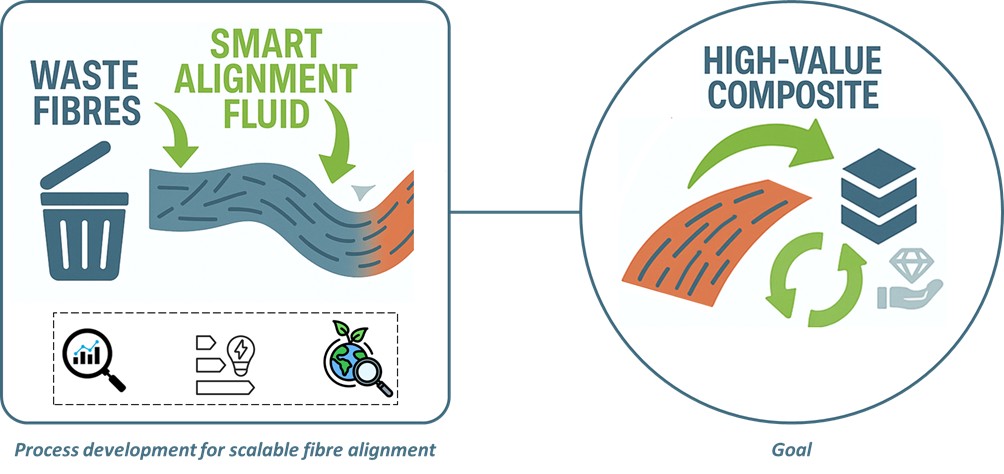

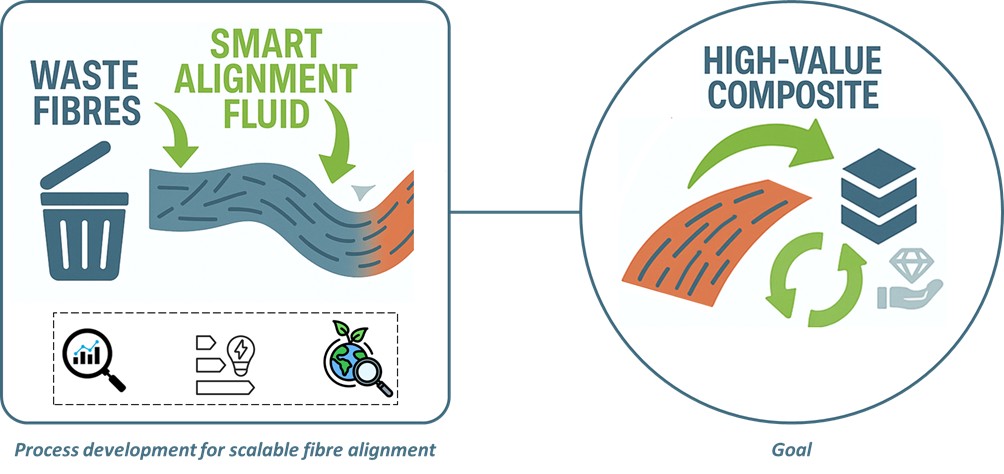

Are you interested in pursuing a PhD at the University of Edinburgh? We seek a highly motivated student to join an ongoing, industry-linked research programme on fibre-alignment technologies to produce truly circular composites. Complementing process-development efforts in the parent project, you will work within an interdisciplinary team to quantify process metrics and undertake parametric tuning and sustainability evaluation.

The circular fibre products emerging from the parent project are intended to integrate within the existing composites value chain and deliver strong fibre-matrix interfacial performance. Drawing on manufacturing, sustainability, materials science and process-engineering insights, your research will inform targeted process refinement efforts within the wider research programme towards addressing current industrial pain points (high energy footprint and low productivity).

Collaborative links with Gen 2 Carbon, Sigmatex and Teijin Europe in the parent project provide exciting opportunities for knowledge-exchange activities and technical site visits during the project.

Project Objectives

- Quantify baseline process metrics (energy use, alignment efficiency, throughput, yield, etc.) across existing waste-fibre alignment workflows using partner and laboratory data.

- Conduct parametric studies to assess how workflow-specific inputs affect alignment, productivity, and energy demand.

- Develop discrete event simulation (DES) models of integrated workflows under alternative process scenarios to explore capacity, bottlenecks, energy load and cost sensitivity.

- Integrate life-cycle & cost-carbon analyses with DES outputs to identify hotspots, quantify improvement potential and generate scale-up decision metrics for industry partners.

Early application is advised as the position will be filled once a suitable candidate is identified.

Training

As a PhD student, you will take part in a wide range of research activities, including collaboration with international researchers and participation in conferences, workshops and seminars. You will work closely with fellow researchers within the Institute for Materials and Processes (IMP) at the University of Edinburgh’s School of Engineering. Regular meetings and collaborative interactions across the group will provide valuable opportunities for technical exchange and peer learning.

You will have access to tailored professional development opportunities through the Institute for Academic Development, and technical training will be provided as needed to support your experimental and analytical work. Close alignment with the parent project and its industry partners will facilitate site visits and knowledge exchange activities, enhancing the real-world relevance of your research.

Note that only applications via the University’s online system will be considered. All applications should include the following documents:

- 2–3-page research proposal

- 1-page motivation letter/personal statement

- Curriculum vitae

- Degree transcripts/certificates

• For any enquiries, please contact: Dr Winifred Obande (w.obande@ed.ac.uk)

• The University of Edinburgh is committed to equality of opportunity for all its staff and students and promotes a culture of inclusivity. Details: https://www.ed.ac.uk/equality-diversity

• Supervisor home page https://eng.ed.ac.uk/about/people/dr-wini-obande

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Further information on English language requirements for EU/Overseas applicants.

We welcome applications from enthusiastic, self-driven and resourceful candidates with a first-class or upper 2:1 UK Honours degree (or international equivalent) in one of the following disciplines:

- Chemical, Mechanical or Manufacturing Engineering

- Systems/Industrial Engineering

- Environmental Engineering

- Any closely related disciplines to the above

Other Essential Requirements:

- 3D CAD proficiency, ideally using Solid Edge, Creo, or SolidWorks.

- Demonstrable experimental laboratory competence and analytical skills.

- University of Edinburgh English-language entry requirements apply.

Desirable Requirements:

- MSc/MEng (or equivalent) in a related field.

- Design of Experiments (DoE) and statistical modelling experience.

- Experience with DES or process modelling tools.

- Familiarity with LCA or cost-carbon analysis (or willingness to learn).

- Some coding experience, ideally in Python or MATLAB.

Further information and other funding options.

There is no funding available for this project, and no additional financial support can be provided. Only self-funded applicants will be considered. If you have your own funding (including government sponsorships), we warmly encourage you to apply.

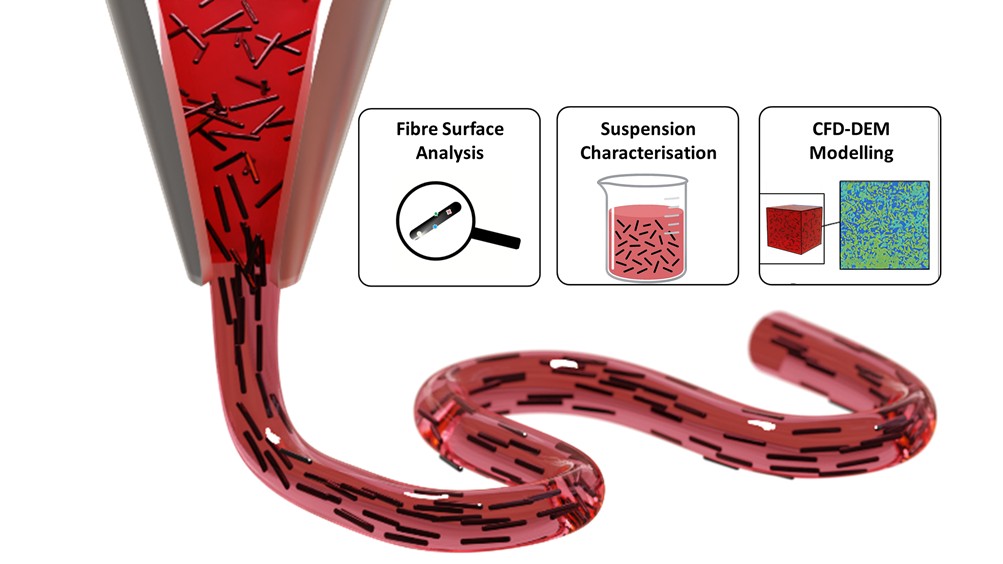

The composites industry is under increasing pressure to transition towards a truly circular economy. As growing demand continues to widen the supply gap, we must recover untapped value that would otherwise be lost to landfilling and incineration, which are resource-intensive and environmentally damaging end-of-life pathways. Where recycled fibres are used, they are often downcycled as fillers and low-value reinforcements in their short and randomly aligned form. A key challenge to the effective reintegration of recycled carbon and glass fibres into high-performance products lies in achieving scalable and energy-efficient fibre alignment from irregular, reclaimed feedstocks. Fibre surface attributes and suspension behaviour in alignment systems play vital roles in determining the alignment efficiency, process stability, and the downstream consolidation and performance of remanufactured composites.

This fully-funded PhD project fits within a wider research programme with industrial partners and an interdisciplinary team working on the development of cross-platform alignment technologies that integrate material science, process engineering and sustainability analysis to deliver scalable solutions for circular composites manufacturing. The successful candidate will contribute to this broader vision by investigating the surface characteristics and suspension dynamics of recycled short fibres used in alignment processes.

Collaborative links with Gen 2 Carbon, Sigmatex and Teijin Europe in the parent project provide exciting opportunities for knowledge-exchange activities and technical site visits throughout the project.

Project Objectives

- Characterise the surface properties of reclaimed carbon and glass fibres from different sources and with varying processing histories.

- Investigate suspension behaviour, including fibre dispersion, settling and agglomeration tendencies under varying conditions.

- Study the influence of suspension properties on alignment efficiency, consolidation behaviour, and interfacial compatibility with traditional composite matrices.

- Explore complementary computational fluid dynamics-discrete element method (CFD-DEM) simulations as a tool to predict fibre-fluid interactions and inform experimental design.

Early application is advised as the position will be filled once a suitable candidate is identified.

Training

As a PhD student, you will take part in a wide range of research activities, including collaboration with international researchers and participation in conferences, workshops and seminars. You will work closely with fellow researchers within the Institute for Materials and Processes (IMP) at the University of Edinburgh’s School of Engineering. Regular meetings and collaborative interactions across the group will provide valuable opportunities for technical exchange and peer learning.

You will have access to tailored professional development opportunities through the Institute for Academic Development, and technical training will be provided as needed to support your experimental and analytical work. Close alignment with the parent project and its industry partners will facilitate site visits and knowledge exchange activities, enhancing the real-world relevance of your research.

Note that only applications received via the University’s online system will be considered. All applications should include the following documents:

- 2–3-page research proposal

- 1-page motivation letter/personal statement

- Curriculum vitae

- Degree transcripts/certificates

• For any enquiries, please contact: Dr Winifred Obande (w.obande@ed.ac.uk)

• The University of Edinburgh is committed to equality of opportunity for all its staff and students and promotes a culture of inclusivity. Details: https://www.ed.ac.uk/equality-diversity

• Supervisor home page https://eng.ed.ac.uk/about/people/dr-wini-obande

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Further information on English language requirements for EU/Overseas applicants.

We welcome applications from motivated, curious, and technically capable individuals with a first-class or upper 2:1 UK Honours degree (or international equivalent) in one of the following disciplines:

- Materials Science

- Mechanical, Chemical or Manufacturing Engineering

- Applied Physics or Physical Chemistry (especially surface, fluid, or particle systems)

- Other closely related disciplines with a strong experimental and analytical focus

Other Essential Requirements:

- 3D CAD proficiency, ideally using Solid Edge, Creo, or SolidWorks.

- Demonstrable experimental laboratory competence and analytical skills.

- University of Edinburgh English-language entry requirements apply.

Desirable Requirements:

- Experience in wet labs, polymer processing and experimental characterisation.

- Familiarity with surface analysis techniques.

- Some knowledge of CFD, DEM, or multiphase flow modelling.

- Some coding experience, ideally in Python or MATLAB.

Further information and other funding options.

Tuition fees and stipend are available for Home and International students.

Applications are also welcome from self funded students, or students who are applying for scholarships from the University of Edinburgh or elsewhere.

Existing buildings entail a third of the energy consumption in the world and contribute a similar share of greenhouse gas emissions. At the same time, they have been shown to have a large potential for improvement in both fronts. Just enhancing operations of what is already in place is estimated to reduce energy and operational emissions by 20% on average.

A significant area of work has focused on whole-building analysis and simulation to rigorously understand performance of existing assets. Here, building audits are combined with holistic physics-based models to improve understanding of what is built and to devise ways to improve operations and retrofit packages. However, such an approach requires specialist knowledge and can easily become onerous given time, interrelationships of physical processes, and resources needed. In addition, it does not link well with metering and building management systems buildings have in place as they only monitor buildings partially.

This project seeks to investigate the role of progressive energy modelling to assist facility managers understand and improve the performance of existing assets. Building systems can be modelled in a wide range of ways, and it is possible to isolate components for dedicated analyses. Then, they can be extended to include further parts relevant to the system. As an example in HVAC systems, heating/cooling generation via heat pumps or boilers could be analysed with a dedicated model, aided by monitoring points typically implemented, like supply/return temperatures or partial loads. Once it is verified that the system works as expected, the model can be extended to represent further parts of the whole system, like losses in distribution systems, emitters, or links with ventilation systems.

Compared to whole-building simulation, this is a bottom-up modelling approach that conceives buildings as a jigsaw of systems that have a closer correspondence with established monitoring practices in facility management. It simplifies complexity, offers faster feedback cycles, retains meaning to explore alternative ways of operating buildings, and could be done in a way that paves the way to whole-building modelling as required.

We are seeking applicants wishing to advance the state of the art in this area, including exploring the role of model complexity, model interoperability, and influence on facility managers' decision-making processes.

This is a joint PhD project between The University of Edinburgh (Dr Daniel Fosas) and Heriot-Watt University (Professor David Jenkins). The context of the work will be the campuses of these institutions and students will have access to their combined training opportunities.

We welcome applications from all qualified candidates, and we wish to particularly encourage applications from groups underrepresented at this level.

To apply to this opportunity, you will need to:

- Meet entry requirements - note this mainly relates to (a) have a degree classification of at least 2:1 or equivalent, (b) have funding, (c) meet English requirements.

- Prepare documentation required for conditional admission in the PhD programme - please note that this requires a formal 2-page research proposal (how to write a proposal).

We are available to discuss and give feedback to applicants that meet entry requirements.

A comprehensive training programme will be provided comprising both specialist scientific training and generic transferable and professional skills. The PhD candidate will be introduced to comprehensive training options, within The University of Edinburgh and Heriot-Watt University.

The candidate will have the opportunity to become a teaching assistant following formal training, as well as opportunities to contribute to wider training and outreach activities. Further training in both academic and interdisciplinary skills will be available as part of Edinburgh’s Institute for Academic Development.

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree.

A background related to building performance simulation and building services engineering would be an advantage for the project. The project will require development of building simulation models, off-the-shelve and bespoke ones, and data mining: familiarity or willingness to learn programming languages like Python, Julia, or R will be essential

Please click on this link for further information on English language requirements for EU/Overseas applicants.

Applications are welcomed from self-funded students, or students who are applying for scholarships from the University of Edinburgh or elsewhere.