Mechanical Engineering

From sandcastles to powder metallurgy, granular materials are ubiquitous in engineering and natural environment. Understanding their behaviour under a range of loading conditions is essential in ensuring the structural integrity of the granular system e.g., landslides, chemical/pharmaceutical applications such as compacted tablets, food processing etc.

The mechanical response of a granular assembly depends on the interaction of the individual grains. In most of the natural and engineering systems, this interaction is further complicated by the presence of fluids and temperature gradient resulting in convective mass transport. The thermomechanical behaviour of the granular assembly depends on the temperature/concentration gradient, viscosity of the fluid, variation in fluid saturation, compressibility of the fluid etc. The presence of fluid would also influence the relative motion of the particles, especially in case of particles with varying size and shapes, and directly contribute to the nature of compaction and flow of the granular assembly.

The aim of the project is to develop a deeper understanding of the mechanics of granular assemblies subjected to convective mass transport and to formulate a multiscale multiphysics model to predict the thermomechanical behaviour of granular assemblies. The model will be developed and calibrated using high quality experimental data acquired at multiple length scales. Custom designed experiments will be conducted in an x-ray CT environment to study the micromechanics of the underlying processes using time resolved x-ray tomography (in 4D).

There are four application areas for this project and the successful candidate would be able to select one of these areas.

Geological/geophysical application: Geothermal systems, particularly Enhanced Geothermal Systems where the energy from underground hot rock/fractured rock is used to generate electricity.

Steel production: Porous coke in the granular assembly of the blast furnace charge provides energy, heat and gas required to reduce the iron ore. Improved design of the granular assembly has potential to minimise the CO2 emission in the steel making process.

Recycled Asphalt Pavements: Reclaimed and recycled asphalt are used in road pavements providing a cost effective and environmentally friendly option with a potential in decarbonising the industry.

Powder bed fusion, a metal additive manufacturing technique: The nature of granular assembly of metal powder bed informs the quality of the finished product.

This PhD project is advertised as a part of the Edinburgh Research Partnership in Engineering, a joint partnership between the University of Edinburgh and Heriot-Watt University. The successful candidate will be supervised by a team consisting of academics from the University of Edinburgh and Heriot Watt University (HWU). The Heriot-Watt University supervisor for this project will be Dr Elma Charalampidou. Some of the experiments involving micro x-ray CT system will be undertaken at HWU.

The selection process is in two phases:

Stage 1: Interested candidates should contact Dr Amer Syed at Amer.Syed@ed.ac.uk by 7 February 2025 with their CV and a covering email. Potential candidates will be invited to an interview. Selected candidate will progress to Stage 2.

Stage 2: Selected candidate will complete a formal application to the University of Edinburgh by 12 February 2025. This application will be assessed by a panel for funding. Please note that this studentship attracts enhanced stipend, while the exact details are yet to be finalised, for 2024, it was £21,400 per annum.

Home and overseas students are encouraged to apply.

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity. Please see details here: https://www.ed.ac.uk/equality-diversity

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Further information on English language requirements for EU/Overseas applicants.

Tuition fees + stipend are available for Home/EU and International students.

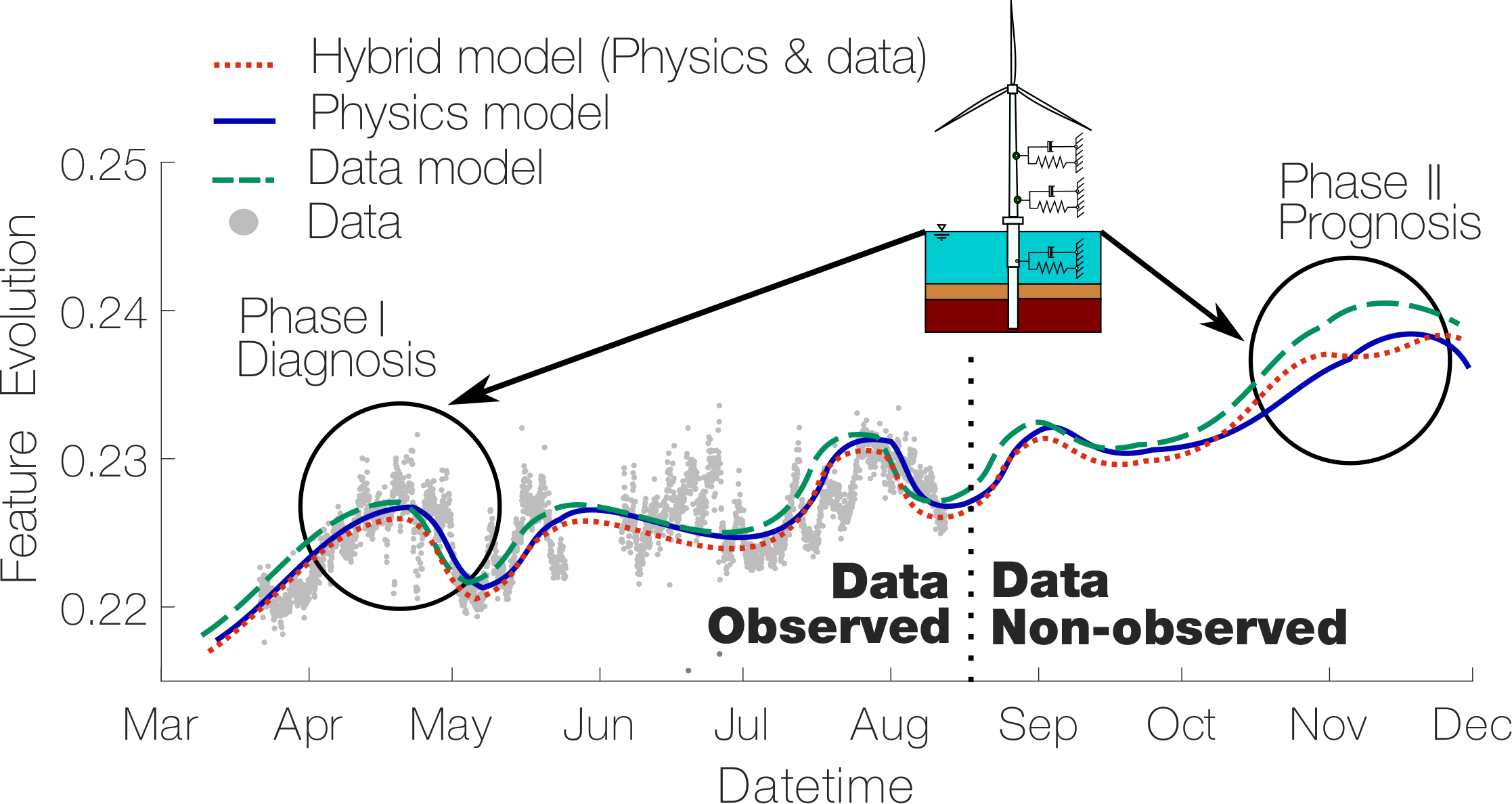

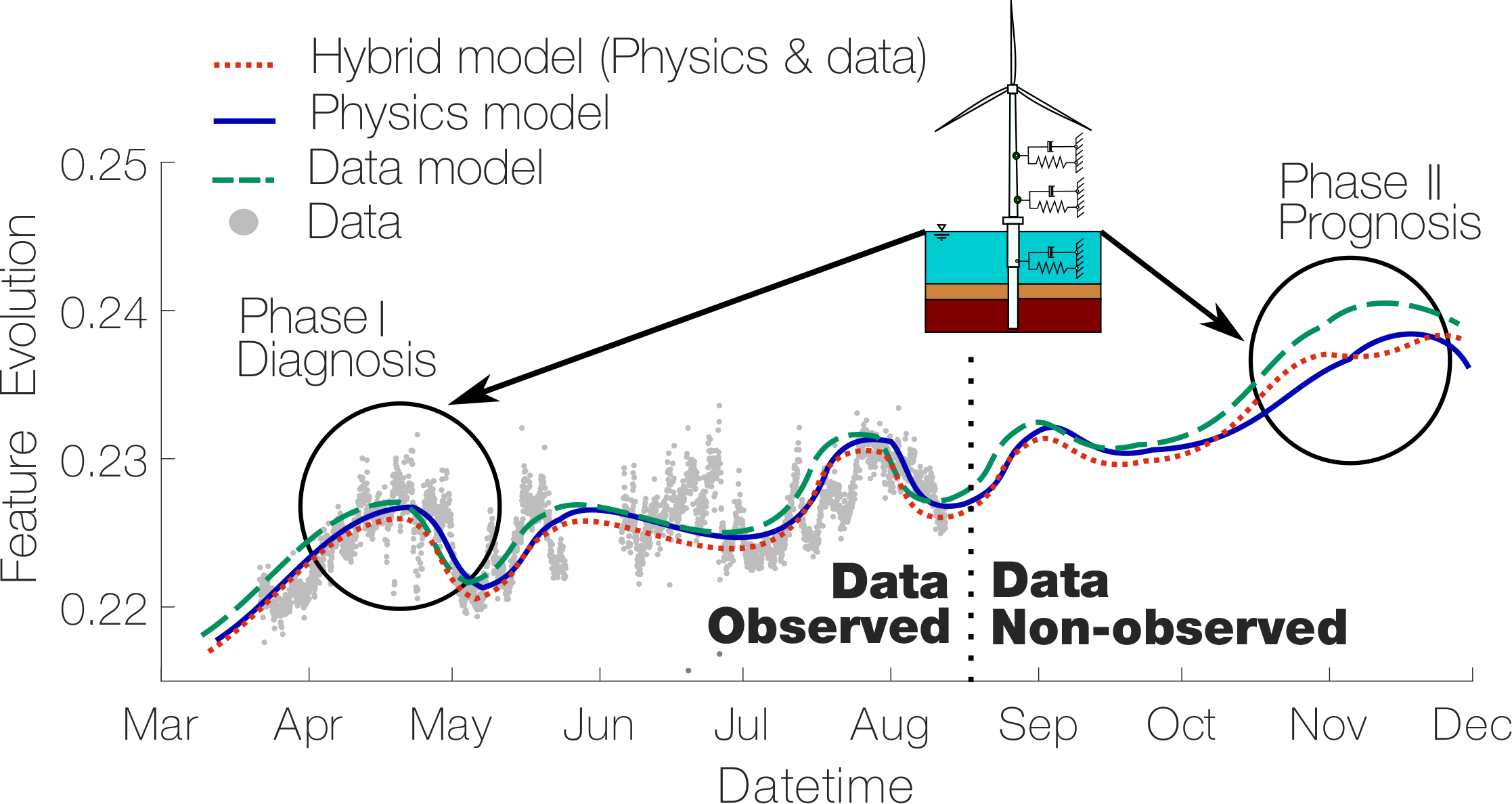

In the context of long-term monitoring applications, there are numerous structural states that exhibit similar behavior but cannot be generalized with a single model (whether data- or physics-based) due to the inherent time-variant nature of structural evolution. Addressing such scenarios necessitates methodologies with adaptable models that can capture the interdependencies between Environmental and Operational Variabilities (EOV) and Damage Sensitivity Features (DSF) at various stages of structural evolution. The challenge lies in determining when distinct structures can be considered pseudo-similar, thereby sharing the same underlying physical properties to better represent the dynamics and associated EOV dependencies. Similarly, the incorporation of physics-based models, with varying levels of fidelity, adds knowledge towards understanding structural changes, which is essential for incorporating interpretable constraints on DSF evolution.

In practice, there are two main Challenges: (i) Robust extraction of DSF for continuous monitoring which are insensitive to EOVs. These DSF should be interpretable during the entire evolution of the structural performance, and they should be able to accommodate dimensionality and complexity reduction of their associated non-linear time-variant nature. (ii) And there is a need of developing measures to quantify and propagate uncertainty towards the estimation of future stages of the structure evolution.

This project is supervised by Dr David Garcia Cava (School of Engineering, University of Edinburgh). It will involve regular interaction with collaborators from academia and industry. Interested candidates may contact the supervisor for further information (david.garcia@ed.ac.uk).

Personal website: https://dgarciacava.github.io/

This advert might close once a suitable candidate is found. Please apply as soon as possible to avoid disappointment.

References

- García Cava, D., Avendaño-Valencia, L.D., Movsessian, A., Roberts, C., Tcherniak, D. (2022). On Explicit and Implicit Procedures to Mitigate Environmental and Operational Variabilities in Data-Driven Structural Health Monitoring. In: Cury, A., Ribeiro, D., Ubertini, F., Todd, M.D. (eds) Structural Health Monitoring Based on Data Science Techniques. Structural Integrity, vol 21. Springer, Cham

- Rashid, D., Giorgio-Serchi, F., Hosoya, N., and Garcia Cava, D. (2024). Physics Informed Gaussian Process for Bolt Tension Estimation. Proceedings of the 10th European Workshop on Structural Health Monitoring (EWSHM 2024), June 10-13, 2024 in Potsdam, Germany. e-Journal of Nondestructive Testing

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity: https://www.ed.ac.uk/equality-diversity

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree.

Applications are particularly welcome from candidates expecting to receive a first-class degree in mechanical engineering, physics, applied mathematics or a closely related subject.

Interests on: Structural mechanics and dynamics, Stochastic modelling and uncertainty quantification, understanding environmental and operational variabilities and their impact in structures and structures for renewable energy is particularly welcome.

Further information on English language requirements for EU/Overseas applicants.

Applications are welcomed from self-funded students, or students who are applying for scholarships from the University of Edinburgh or elsewhere.

Competition (EPSRC) funding may be available for an exceptional candidate but please note you must be a UK student or an EU student who has pre-settled/settled status and has lived in the UK for at least 3 years.

This PhD project aims to delve into the complex mechanisms of mechanobiology and their crucial influence on human embryo development. A growing body of evidence suggests that mechanical forces, alongside biochemical signals, play a significant role in cellular function and organismal development. However, the specific interactions and effects of these forces during the early stages of human development remain largely unexplored due to technical and ethical limitations. This research seeks to bridge this gap by employing state-of-the-art techniques in biomechanics, developmental biology, and computational modeling to examine how mechanobiological forces guide cell differentiation, tissue morphogenesis, and organ development during the first weeks of pregnancy.

The study will focus on three primary objectives: (1) To measure and analyze the mechanical forces exerted on cells in the developing embryo, (2) to assess how these forces influence signaling pathways and gene expression related to cell fate decisions, and (3) to determine the implications of aberrant mechanical forces on developmental anomalies in both embryonic and extraembryonic tissues

The project will utilize advanced microfabricated devices capable of simulating the mechanical environment of the womb. These devices will house cells and be subjected to controlled mechanical stimuli, mimicking the natural stresses and strains experienced during early embryogenesis. Live cell imaging techniques will allow for real-time observation and quantification of mechanical forces at play.

Simultaneously, cutting-edge genetic sequencing technologies will monitor changes in gene expression in response to different mechanical conditions. By integrating these data, the project intends to construct a detailed map of the mechanotransduction pathways that are active during early development.

By focusing on a largely underexploited yet critical area of embryonic development, this research is expected to provide groundbreaking insights into the role of mechanobiological forces in human embryo development. Understanding these interactions will not only refine our fundamental knowledge of developmental biology but could lead to improved clinical protocols in assisted reproduction technologies (ART) and potentially pave the way for novel interventions for developmental disorders.

Location and skills

The project will be carried out at the Institute for Bioengineering (IBioE) at the University of Edinburgh. The student will attain skills in mammalian cell culture, embryo models, microfluidics, materials, optical microscopy, as well as data and image analysis.

Career development

Institutional and Peer Support: you will benefit from an excellent supportive environment at the School of Engineering within the Institute for Bioengineering at The University of Edinburgh.

International Collaboration: the successful student will also have to opportunity visit and interact with our network of international collaborators.

Impactful publications and dissemination: the student will also benefit from strong support towards publications in world class journals and participation in major conferences as well as support to undertake outreach to the wider public.

Teaching and Research Development: the potential student will have the opportunity (once trained and familiar with relevant materials) to become a teaching assistant for courses offered at the School of Engineering.

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity: https://www.ed.ac.uk/equality-diversity

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Further information on English language requirements for EU/Overseas applicants.

We welcome applications from self-funded students

The advent of Industry 4.0 has ushered in a new era of manufacturing, marked by the integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and digital twins. This research project will investigate the methodologies and technologies necessary to create an accurate and dynamic digital twin that reflects the real-time status of a manufacturing process, thereby enabling enhanced decision-making, predictive maintenance, and improved production efficiency.

This project will be jointly supervised by:

Prof Prof Jonathan Corney j.r.corney@ed.ac.uk

Dr Matjaz Vidmar matjaz.vidmar@ed.ac.uk

Smart Products Made Smarter

The PhD project forms part of a larger Prosperity Partnership Programme, Smart Products Made Smarter, a collaboration with Heriot-Watt University, University of Edinburgh and Leonardo.

We are pleased to invite applications for a PhD studentship to work as part of a leading team of experts. This studentship will be supported by an enhanced stipend of £20,716 per year over 3.5 years.

This grant, sponsored by the EPSRC, is a collaboration between academia and Leonardo. There are currently PhD opportunities available to work on diverse topics as part of this collaborative team. The work will involve strong links with industry.

The research addresses a broad range of challenges. These challenges exemplify future product lifecycle management from smart concept, design, development and manufacture to enhanced end-user capability, united by a common digital thread to enable smarter products to be made smarter. Each challenge area has clearly identified initial research themes and associated research challenges to be addressed and these are indicated below:

Challenge 1 (C1) the Making challenge: To create new hybrid manufacturing processes, that combine multiple Additive Manufacturing (AM) process with precision machining and coating processes to create components that disrupt the traditional functional trade-offs of Size, Weight and Power (SWaP) through techniques such as varying the material properties within a part and harnessing the digital production of optical components.

Challenge 2 (C2) the Manipulation challenge: To create new handling processes that fully exploit the digital data flows which define custom components whose shape and functionality is tailored to production by dexterous, highly adaptable robots that are programmed dynamically.

Challenge 3 (C3) the Computation challenge: To create new signal processing & machine learning methodologies that enable intelligent, digital & connected sensor products while mitigating the data deluge from the multiple sensors produced by Leonardo operating across the EM spectrum.

The themes represent areas that could form the basis of your PhD. These PhD positions offer great flexibility and we welcome the opportunity to explore other ideas & themes.

Please note that this advert will close as soon as a suitable candidate is found.

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity: https://www.ed.ac.uk/equality-diversity

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Further information on English language requirements for EU/Overseas applicants.

Please note that as this is a defence based project, only UK/EU students are eligible to apply. International applicants are not eligible.

Tuition fees + stipend are available for applicants who qualify as:

- a UK applicant

an EU applicant (International/non EU students are not eligible)

Funding is available through EPSRC Prosperity Partnership Programme. As this is a defence related project there are nationality restrictions (see above).

The Place - Edinburgh Research Partnership in Engineering (ERPE)

ERPE is a strategic alliance between Heriot-Watt University (HWU) and the University of Edinburgh, UoE, as two of the UK's leading research universities in STEM. ERPE works with academics, industry and public sector partners to deliver world-leading engineering solutions and create commercial, social, environmental and economic impact. This PhD project involves a collaboration between the Institute for Multiscale Thermofluids (IMT) at the School of Engineering of UoE, and the School of Engineering and Physical Sciences (EPS) at HWU. IMT is recognised in theoretical and experimental characterization of interfacial and reactive multiphase flows, while EPS combines a longstanding reputation in the energy sector and a pioneering role in the UK industrial decarbonisation with the new Global Research Institute GRI iNetZ+. The successful candidate will be co-supervised by Dr Khushboo Pandey from UoE and Dr Victor Francia from HWU. They will join Experimental MultiPhysics and MultiPhase flow group, E(MP)2 Group at UoE, and xFlow (Complex Flow Technologies) at HWU. The E(MP)2 Group at UoE focuses on experimental investigation and theoretical modelling of complex muliphase systems, specifically, particle dynamics and spray characteristics in extreme and turbulent conditions for developing sustainable energy technologies for power and propulsion. xFlow focuses on technology development, looking at new platforms with potential to disrupt the energy and manufacturing sectors. They intensify gas-solid operations and integrate them in the design of new circular processes to allow traditional chemical and biochemical industries to adopt sustainable practices quickly and efficiently.

The Project

In this project, we will work towards a fundamental understanding of complex particle dynamics in near-wall flow structures, such as deposition, resuspension and agglomeration. Deposition and resuspension are critical phenomena across a broad range of disciplines. Transport, deposition and resuspension of particulate matter and solid aerosols is ubiquitous in nature, and it has a direct impact in sectors spanning heath care (transmission of disease vectors) to renewable energy and space exploration (efficiency of solar panels), and a very broad range of manufacturing and environmental technology, from deposition on traditional multiphase reactors to water remediation technology, and the manufacturing of advanced materials via spray drying, granulation, coating, electrospraying. This project will advance the fundamental understanding of particle-particle interactions in wall-bounded flows, how particle flow, interact, deposit, agglomerate and resuspend in shear and swirling turbulent boundary small-scale wind tunnel and vortex flow chambers at the Small Research Facility for Multi-phase Flows at High Pressure and Temperature (UoE) and within REVOC (EPSRC-funded project k768£ FE) at xFlow laboratories (HWU). The PhD candidate will employ state-of-the-art flow visualization diagnostics (high-speed shadowgraphy, Particle Image Velocimetry, among others) to understand the particle dynamics in wall-near regions and quantify transport properties, flow structures and rate of deposition, resuspension and agglomeration ideal particulate systems. The fundamental dynamics studied here will find application in the validation of high-fidelity models of particle flow and the development of digital twins for a broad range of processes, from healthcare to energy and sustainable manufacturing.

Interested candidates are advised to contact Dr Khushboo Pandey kpandey@ed.ac.uk from UoE and Dr Victor Francia, v.francia@hw.ac.uk from HWU.

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity. Please see details here: https://www.ed.ac.uk/equality-diversity

The selected candidate will be invited to apply to a PhD position via the University of Edinburgh website and will be put forward to a competitive selection process by ERPE, the Edinburgh Research Partnership in Engineering.

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Further information on English language requirements for EU/Overseas applicants.

The ideal candidate would have a Master Level degree in mechanical / chemical engineering / physics or a related discipline with outstanding record. The candidate would have a strong interest in experimental multiphase flow and flow visualisation. The candidate would also need to be fluent in English, be proactive, independent and with a can-do mentality.

Applications to be received by 7 / 02 / 2025. The expected start date is September 2025 after the completion of a competitive selection process within ERPE. Scholarships are open to UK applicants or exceptional oversea applications. Interested candidates are advised to contact Dr Khushboo Pandey kpandey@ed.ac.uk from UoE and Dr Victor Francia, v.francia@hw.ac.uk from HWU.

- A CV

- BEng/Meng/MSc grades

- A motivation letter explaining your interest/aptitudes for this position

Applications are welcomed from self-funded students, or students who are applying for scholarships from the University of Edinburgh or elsewhere.

Nucleate boiling is a type of boiling mechanism where the heat is transferred from a hot surface to a liquid through the formation and release of vapor bubbles. This process occurs at discrete points on the surface where the liquid is in direct contact with heat. During nucleate boiling, small bubbles of vapor form at nucleation sites, typically surface imperfections, and grow until they are buoyant enough to detach and rise through the liquid. Surface modification is a passive method to increase heat transfer in nucleate boiling by controlling bubble nucleation and detachment using structures or coatings that modify a surfaces morphological parameters.

Recently, we developed new techniques to modify surfaces with regions that could act as nucleation sites and provide easy bubble detachment. These patterned liquid-like surfaces are based on Slippery Covalently Attached Liquid-like Surfaces (SCALS). In this experimental project, you will tackle questions involving nucleate boiling on patterned liquid-like surfaces: we are interested in understanding how these surfaces act under boiling conditions and their effects on the efficiency of heat transfer and maintaining a stable heat flux. By answering questions like these, you will be pushing the boundaries of knowledge in this field and kick-start your postgraduate career.

If successful, you will become a member of the Wetting, Interfacial Sciences and Engineering Group within the Institute for Multiscale Thermofluids at the School of Engineering. You will join a vibrant community of PhD students, postdoctoral research associates and academics working in various aspects of surfaces and wetting, and will develop as a scientist benefiting from our track record, which includes publications in top journals, international collaborations and contributions to key international conferences.

Please note that the supervision team will include:

Principal supervisor

Dr Gary Wells: https://www.eng.ed.ac.uk/about/people/dr-gary-wells

Assistant supervisors

Professor Glen McHale: https://www.eng.ed.ac.uk/about/people/professor-glen-mchale

Dr Rodrigo Ledesma Aguilar: https://www.eng.ed.ac.uk/about/people/dr-rodrigo-ledesma-aguilar

Please note that if a suitable candidate is found prior to the closing date, then the position will be closed and the advert will be removed.

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity. Please see details here: https://www.ed.ac.uk/equality-diversity

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree.

We expect that you will have a good degree in Engineering or Physics with an experimental and modelling background. We are particularly interested to hear from applicants with experience in surfaces, fluids and/or phase change.

Please note that if a suitable candidate is found prior to the closing date, then the position will be closed and the advert will be removed.

Further information on English language requirements for EU/Overseas applicants.

Applications are welcomed from self-funded students, or students who are applying for scholarships from the University of Edinburgh or elsewhere.

The Institute for Energy Systems at the University of Edinburgh invites applications for a PhD studentship in "Next-Generation Electricity Market Modelling for Sustainable Energy Systems." This project offers a unique opportunity to contribute to transformative research in the transition of electricity markets in the UK.

The UK electricity market requires significant reform to meet the demands of a net-zero energy future. This project will look to help provide quantitative evidence to support the design of future electricity markets by developing the next-generation of open-source electricity market models. Model development will ideally build on state-of-the-art tools such as PyPSA for energy system optimisation and AMIRIS for agent-based modelling of market behaviour.

The research will focus on rethinking the UK’s electricity market design, addressing key REMA challenges, including locational signals, promoting investment in renewables, and enhancing system flexibility. By integrating renewable energy, energy storage (e.g., hydrogen production), and demand-side participation into these models, the project aims to optimise market efficiency while supporting the UK’s broader decarbonisation goals.

The candidate will develop a wide range of skills in simulation, optimisation, and data analysis which are widely applicable to future career development. Additionally, there are opportunities for engaging with an open and inclusive community of open-source energy system developers both within IES and globally.

*NOTE: Competitive funding may be applied for if applications are received before the 31st January, 2025 via EPSRC DLA scheme - https://www.ukri.org/news/major-investment-to-support-the-next-generation-of-researchers/

**NOTE: This position will remain open until filled. Early contact is highly recommended.

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity. Please see details here: https://www.ed.ac.uk/equality-diversity

Essential background:

2.1 or above (or equivalent) in Engineering, Mathematics, Physics, Energy Engineering/Economics, Informatics, or similar

Programming in Python, Julia or other high-level language

Desirable background:

Knowledge of energy economics

Experience of energy system modelling and optimisation

Data analysis, optimisation and/or machine learning

Further information on English language requirements for EU/Overseas applicants.

Applications are welcomed from self-funded students, or students who are applying for scholarships from the University of Edinburgh or elsewhere.

A major challenge for defence & security laser systems is managing the heat generated and differential thermal expansion of the different components in the system. A compounding challenge is the vast range of ambient temperatures in which these systems need to operate without thermal distortion. However, additive manufacturing gives the unique opportunity to tailor the material properties, and design the support structures, to manage different thermal expansions of optics, laser crystals, laser diodes, etc.

The research will focus on developing new material combinations in powder-bed laser fusion additive manufacturing, as well as to design and demonstrate new mechanical 3D printed structures, with the specific aim of managing and matching the thermal expansion coefficients of laser system components, while maintaining the required precision and stability of these high-end laser systems.

This project will be jointly supervised by:

- Prof Jonathan Corney j.r.corney@ed.ac.uk

- Dr Sam Tammas-Williams s.tammaswilliams@ed.ac.uk

Smart Products Made Smarter

The PhD project forms part of a larger Prosperity Partnership Programme, Smart Products Made Smarter, a collaboration with Heriot-Watt University, University of Edinburgh and Leonardo.

We are pleased to invite applications for a PhD studentship to work as part of a leading team of experts. This studentship will be supported by an enhanced stipend of £20,716 per year over 3.5 years.

This grant, sponsored by the EPSRC, is a collaboration between academia and Leonardo. There are currently PhD opportunities available to work on diverse topics as part of this collaborative team. The work will involve strong links with industry.

The research addresses a broad range of challenges. These challenges exemplify future product lifecycle management from smart concept, design, development and manufacture to enhanced end-user capability, united by a common digital thread to enable smarter products to be made smarter. Each challenge area has clearly identified initial research themes and associated research challenges to be addressed and these are indicated below:

Challenge 1 (C1) the Making challenge: To create new hybrid manufacturing processes, that combine multiple Additive Manufacturing (AM) process with precision machining and coating processes to create components that disrupt the traditional functional trade-offs of Size, Weight and Power (SWaP) through techniques such as varying the material properties within a part and harnessing the digital production of optical components.

Challenge 2 (C2) the Manipulation challenge: To create new handling processes that fully exploit the digital data flows which define custom components whose shape and functionality is tailored to production by dexterous, highly adaptable robots that are programmed dynamically.

Challenge 3 (C3) the Computation challenge: To create new signal processing & machine learning methodologies that enable intelligent, digital & connected sensor products while mitigating the data deluge from the multiple sensors produced by Leonardo operating across the EM spectrum.

The themes represent areas that could form the basis of your PhD. These PhD positions offer great flexibility and we welcome the opportunity to explore other ideas & themes.

Please note that this advert will close as soon as a suitable candidate is found.

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity: https://www.ed.ac.uk/equality-diversity

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Please note that as this is a defence based project, only UK/EU students are eligible to apply. International applicants are not eligible.

Further information on English language requirements for EU/Overseas applicants.

Tuition fees + stipend are available for applicants who qualify as:

a UK applicant

an EU applicant (International/non EU students are not eligible)

Funding is available through EPSRC Prosperity Partnership Programme. As this is a defence related project there are nationality restrictions (see above).

If we stretch a material, such as a rubber band, in one direction we observe it contracts in the lateral direction. However, a material can be designed to be counterintuitive so that when it is stretched in one direction it also expands in the lateral direction. A material with this unusual property is called a mechanical metamaterial (an auxetic material). The pore sizes in such materials can therefore be changed by strain. A mechanical metamaterial with a hydrophobic surface can be converted by strain to a super-water-repellent material or to a porous material.

In this project, the focus will be on creating hydrophobic mechanical metamaterials using foams and characterizing their properties when in contact with different liquids. The project will also consider a possible application in the programmable separation of oil-water mixtures and de-fouling of materials. The project will investigate whether strain might be used as a switch to allow oil to either be blocked to to pass through the material and whether strain can be used to release particulates blocking the material when it is used as a filter.

The PhD researcher will be part of the Wetting, Interfacial Sciences and Engineering Group within the Institute for Multiscale Thermofliuds. You will join a vibrant community of PhD students, postdoctoral research associates and academics working in various aspects of surfaces and wetting. The student will attain skills in materials preparation, surface coating, construction of experimental set-ups, and measurement techniques and characterization techniques.

It is expected that the applicant will have a good degree in chemical engineering, mechanical engineering, materials science, physics, or a related discipline.

Please note that if a suitable candidate is found prior to the closing date, then the position will be closed and the advert will be removed.

For further information on this project, please refer to the following website: http://www.naturesraincoats.com/

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree. Further information on English language requirements for EU/Overseas applicants.

Applications are welcomed from self-funded students, or students who are applying for scholarships from the University of Edinburgh or elsewhere.

A wide spectrum of target thermoplastic materials can be manufactured by tailoring polymer blends to achieve particular combinations of end-user performance (e.g. mechanical, electrical, structural support) properties, important in various industrial sectors, especially in extreme-condition environments. These polymeric material classes include the widely used polyolefins (PE, PP), but also others derived from higher-MW monomers (PS, PVC, PVP, PC, PTFE, etc. ). The key challenge here is to computationally predict (and experimentally confirm) optimal blend compositions which can be manufactured reasonably easily (high processability via extrusion, blow moulding, etc.), in order to achieve formulated products which achieve (or exceed) the said end-user properties, under reasonable total (fixed+operating) cost per unit mass.

Over the years, the UoE Polymer Engineering Laboratory has compiled a wealth of experimental datasets for many blend-condition combinations (virgin/recycled feedstocks, input molecules, temperatures, extrusion/moulding settings, product macro-dimensions) e.g. Polymers 2023, 15(21), 4200 (https://doi.org/10.3390/polym15214200). Constructing first-principles mathematical models which combine macromolecular physical chemistry (e.g. Flory-Huggins theory) descriptions with mass/heat balances towards end-product property estimation, rigorous unit operation (e.g. extruder) design and optimisation is extremely cumbersome, both due to mathematical complexity, but even more so due to the extreme and pervasive parametric uncertainty hampering such efforts.

Therefore, this PhD project aims to combine state-of-the-art Artificial Intelligence (AI) and Machine Learning (ML) methodologies in order to explore optimal blending and processing conditions for polymeric material classes, towards developing materials which will achieve high performance indices for key target properties, while also ensuring high processability and cost-optimal manufacturing at scale.

Strong computational skills, an interest in statistics, and prior experience in numerical methods/software (MATLAB, Python) are essential; prior ML-based project work is desirable.

- https://www.eng.ed.ac.uk/about/people/dr-dimitrios-i-gerogiorgis

- https://vasileioskoutsos.wixsite.com/softmaterials

The University of Edinburgh is committed to equality of opportunity for all its staff and students, and promotes a culture of inclusivity. Please see details here: https://www.ed.ac.uk/equality-diversity

An undergraduate degree in Chemical/Mechanical Engineering, or a closely related area (Physics, Chemistry), with a strong background in computational modelling.

Minimum entry qualification - an Honours degree at 2:1 or above (or International equivalent) in a relevant science or engineering discipline, possibly supported by an MSc Degree.

Further information on English language requirements for EU/Overseas applicants.

Applications are welcomed from self-funded students, or students who are applying for scholarships from the University of Edinburgh or elsewhere.