Location:

Hudson Beare Building, Classroom 8

Date:

10:00 – 10:30 : Talk 1 by Dr. Patricia (Patty) Weisensee

Droplets Change Phase: Condensation and Evaporation

Phase change dominates many natural and industrial processes, including the water cycle (evaporation from lakes and oceans, and condensation in clouds), high power electronics cooling, and materials manufacturing and processing. In this talk I will highlight two such phenomena: Condensation and evaporation. I will focus on droplets, which are omnipresent in our daily lives, and hence understanding their behavior during phase change is critical to allowing us to use them for specific applications.

During condensation on external surfaces, the formation and mobility of droplets is crucial to maintaining high heat transfer rates and to avoid flooding. So-called lubricant-infused surfaces (LIS), where a thin oil layer covers a rough or porous surface, are promising candidates to sustain stable dropwise condensation. In this talk I will show that micro-droplets exhibit extremely high mobility on LIS, unlike on traditional solid hydrophobic surfaces, due to the formation and overlap of oil menisci. These wetting ridges introduce an attractive capillary force, which leads to high droplet sweeping and re-nucleation rates. Furthermore, this droplet sweeping is independent of gravity, potentially allowing for use of this technology in mobile or space applications.

In the second part of this presentation I will present very recent results from droplet evaporation studies on heated wettability-patterned horizontal and vertical surfaces. On vertical surfaces, droplet shapes are non-symmetrical, leading to a single internal convection vortex rather than two. This irregular flow pattern leads to non-uniform temperature distributions at the droplet-substrate interface, and enhances the net heat transfer to the droplet. This ongoing project also elucidates the use of wettability-patterned surfaces to enhance the efficiency of droplet or jet impingement cooling applications.

Bio

Dr. Patricia (Patty) Weisensee is an Assistant Professor of Mechanical Engineering and Materials Science at Washington University (WU) in St. Louis, Missouri. She earned her PhD in Mechanical Engineering from University of Illinois at Urbana-Champaign in 2016. She received a Diplom-Ingenieur in Mechanical Engineering from TU Munich in 2013 and also holds a M.S. in Materials Sciences from University of Illinois, Urbana-Champaign (2011). For her work on condensing steam bubbles in sub-cooled flow, Patty received the Siemens Energy Award 2014. Patty is an alumna of the German National Academic Foundation.

At WU, Patty is the head of the Thermal Fluids Research Group, which focuses on understanding the interplay of fluid dynamics and heat transfer of droplets and other multi-phase systems. Practical applications of interest are additive manufacturing, phase change heat transfer for thermal management and thermal storage, and droplet interactions with biological systems. To fundamentally study these thermal-fluidic interactions, we combine multiple experimental techniques, such as high-speed optical and infrared (IR) imaging, interferometry, confocal fluorescence microscopy, and conventional heat transfer measurements. Current projects include the characterization of melt pool dynamics during metallic 3D printing, dropwise condensation heat transfer on lubricant-infused surfaces (LIS), the wettability of graphene, and droplet impact dynamics on hierarchical and bi-philic surfaces.

10:30 – 11:00 : Talk 2 by Dr. Masahiro Motosuke

Electrokinetic microfluidic modulation of interfacial flow and reaction

In many microfluidic systems (microTAS, Lab-on-a-Chip, etc…), interfacial-related phenomena plays a key role for the performance of the systems. Especially, solid-liquid interface is of importance in sensing and detection processes. Therefore, an appropriate control of liquid flow in the vicinity of solid surface can provides an improved detection or enhanced mixing in various microfluidic platforms which can be exploited in many fields.

Our research group has investigated an electrokinetic flow manipulation at the solid liquid interface in microchannels. One example is alternating-current electroosmosis for particle manipulation. This relies a nanoscopic nonlinear electromagnetic force due the gradient of the electrical properties of liquid under inhomogeneous electric field, an tangential interfacial flow is generated. This interfacial flow is utilized to arrange or accumulate suspended micro/nanomaterials in the bulk liquid to a certain area on the surface. Appropriate design of the electrode array leads versatile applications of particle manipulation. In the seminar, other recent approaches of controlled interfacial flow in the microfluidic system will be introduced.

Bio

Masahiro Motosuke is an Associate Professor in the Department of Mechanical Engineering at Tokyo University of Science. He received his B.S, M.S and Ph.D degrees at Keio University. Then he started to work in Department of Mechanical Engineering at the Tokyo University of Science as a Research Associate, and then became an Assistant Professor in the same department. From 2010 to 2011, he was in Department of Micro-/Nanotechnology in Technical University of Denmark. Then he came back to Tokyo University of Science as Junior Associate Professor and thereafter Associate Professor. He serves important roles in Japanese Academic Societies, e.g., Board member in Visualization Society of Japan, Director in Japan Society of Thermophysical Properties, Committee Head of Public Relations in Heat Transfer Society of Japan and Secretary of Domestic Journal in Japan Society of Fluid Mechanics . His research interest is in transport phenomena and advanced sensing in micro/nanofluidic system, micro/nanoparticle manipulation and detection, microfluidic cell assay and interfacial flow control in micro/nanoscopic domain.

11:00 – 11:20 : Coffee Break

11:20 – 11:50 : Talk 3 by Prof. Michael Bestehorn

Mechanically driven thin liquid films: instabilities and pattern formation

Selection of the talk on Liquid Films Described by Reduced Models

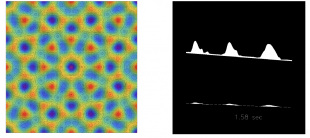

The emergence and dynamics of macroscopic patterns in spatially extended fluid systems can be described by first principles, namely the conservation laws for mass, momentum, energy, etc. If on the other hand one of the space dimensions is distinguished for physical or geometrical reasons, dimension-reduced models may be derived successfully by integrating out that dimension. Here we consider (thin) liquid films where the particular dimension is the vertical one. Another way of dimension reduction is obtained by enslaving many temporally fast modes by only the few slow modes normally present in the vicinity of instabilities. The Swift-Hohenberg equation and its extensions describe qualitatively well the behaviour of several pattern forming convection instabilities.

After an introduction to these methods, the situation of parametrically excited films by mechanical vibrations will be studied in more detail. Linear as well as nonlinear results of the reduced model will be presented and compared to findings of the full set of hydrodynamic basic equations. Numerical solutions in the nonlinear regime reveal interesting new patterns like confined traveling pulses or quasi-periodic surface structures.

Bio

Michael Bestehorn studied Physics at the University of Stuttgart. In the following he worked at the Institute for Synergetics in Stuttgart where he received his PhD and the Venia Ligendi in Theoretical Physics. Since 1999 M. Bestehorn is the head of the department for Theoretical Physics, Statistical Physics and Nonlinear Dynamics at the Brandenburg University of Technology in Cottbus, Germany. He gives lectures in theoretical physics, computational physics and fluid dynamics. His research interests are focused on hydrodynamic instabilities and pattern formation in fluids.

11:50 – 12:20 : Talk 4 by Dr. Ken Yamamoto

Blood-typing test with bubbles: multiphase system is complicated, yet simple

In our previous study, we demonstrated that exploiting a motion of dispersed phase can significantly enhance the mixing in microscale [Sakurai et al., Analyst 144 (2019) 2780–2787]. Here we applied the developed method for a fully-automatic blood-typing test device. The device is designed for non-expert users who load blood, wait for five minute, and see the test result without any optics. Although multiphase systems are generally regarded as complicated and sensitive to control, our device indicate that the multiphase systems can be simple if they use the additional phase in multiple steps; no electrodes and no external power sources are required.

Bio

Ken Yamamoto is an Assistant Professor at Tokyo University of Science.

Ken studied mechanical engineering at Tokyo Metropolitan University, receiving B.Eng., M.Eng., and Ph.D degrees. He started to work at current position after serving two years at Keio University as a Research Assistant Professor.

He has research experiences in wetting phenomena, microscale multiphase flows, micro total analysis systems, and droplets and bubbles.

12:30 – 13:00 : Lunch Break with Pizza