Post date:

Matthew Donora, who recently completed the viva for his PhD in smart contact lenses is Head of Engineering at OpenCell – a company which makes biotech laboratories in shipping containers. He has been working on the initiative alongside researchers from his company and King’s College London.

Rapid response

Significantly, the team have developed the first known example of a fully functional COVID-19 testing lab – as opposed to individual components – that can be instantly deployed anywhere in the world.

They have just been awarded an Innovate UK grant for business-led innovation in response to global disruption, to help them translate the practical applications of their research still further.

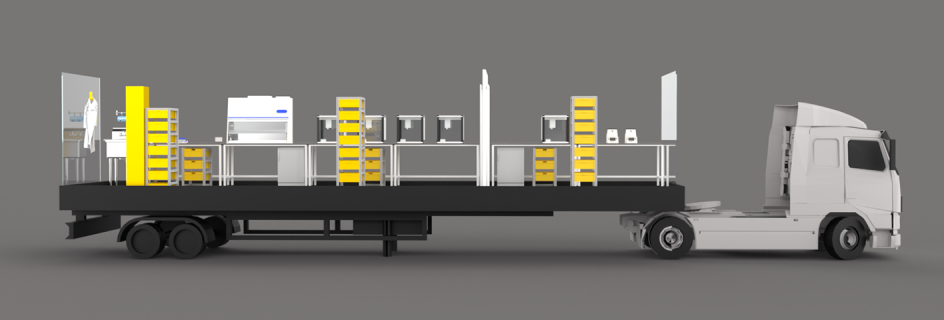

Most of the lab work is automated using low-cost liquid handling robots, which perform a qPCR – known as the gold-standard nucleic acid detection test – to detect the presence of the SARS-CoV-2 virus. The system is housed in a shipping container for rapid response, and the project is collectively known as CONTAIN to reflect this.

Open source

Crucially, the CONTAIN team is using processes and chemical reagents which are available for anyone to use worldwide, and are compatible with the Centre for Disease Control’s (CDC) international guidance on Covid-19. The open-source nature of their work means that they can leapfrog supply chain restrictions caused by the ‘proprietary’ nature of equipment currently employed for testing.

At present, COVID test equipment is designed so that users can only employ test kits and consumables created by a small number of manufacturers.

Donora, who has recently completed his PhD studies in the School’s Institute of Integrated Micro and Nano Systems (IMNS) under the supervision of Professor Ian Underwood, explained: “I started working at OpenCell just before my PhD viva, and when the global outbreak started we dropped everything to work on a response.

“Our company makes biotech laboratories in shipping containers, and we designed a BSL2+ COVID-19 testing laboratory in one of these units, which can be transported anywhere in the world using standard sea and land freight. As Head of Engineering, I worked in particular on developing an automated RT-qPCR testing protocol using low-cost liquid handling robots, as well as the lab design and operational logistics.”

Spin-out innovation

Professor Underwood commented: “Matthew has not hung around after recently completing a prolific PhD in which he developed a technology capability, integrated in a smart contact lens, for sensing biomarkers in tear fluid. I expected him to go far, but the speed with which he is making a real difference delights me and the application OpenCell is targeting could not be more worthwhile or timely.

“With my encouragement and mentoring, many of the PhD students have followed my own path, and gone on to found or join startups, spin-outs and young high-growth companies.”

The project is the subject of a preprint research paper that will appear on the BioRxiv website, before it is peer reviewed for publication in scientific journals.