Post date:

Since the Covid-19 pandemic hit the UK in March 2020, the School of Engineering community has joined forces to combat the virus and to mitigate its effects through a range of research and practical activities.

Initiated and partly coordinated by Dr Katherine Dunn, the School’s Covid-19 response has been mobilising our in-house resources and expertise to tackle emerging challenges created by the pandemic. This work has been carried out in collaboration with frontline medics, clinical engineers, medical physicists, NHS procurement, industry, government advisors, charities and others.

Here is an overview of some of the Covid-19-related initiatives our staff, students and alumni have been involved in to date.

Analysing the efficacy of face coverings

In May, a study led by the School of Engineering found that wearing a face mask or other covering over the mouth and nose reduces the forward distance travelled by an exhaled breath by more than 90 per cent. This finding hit the news in over 20 countries, reaching an audience of over 4 billion people.

The researchers used a technique called Background Oriented Schlieren imaging that enables scientists to measure the distance and direction travelled by air expelled when a person breathes or coughs. Measurements were taken from people wearing different face coverings while standing or lying down, and from a manikin connected to a cough-simulating machine.

The team tested seven types of face covering – including medical-grade and home-made masks – and found that they could all potentially help limit the spread of Covid-19.

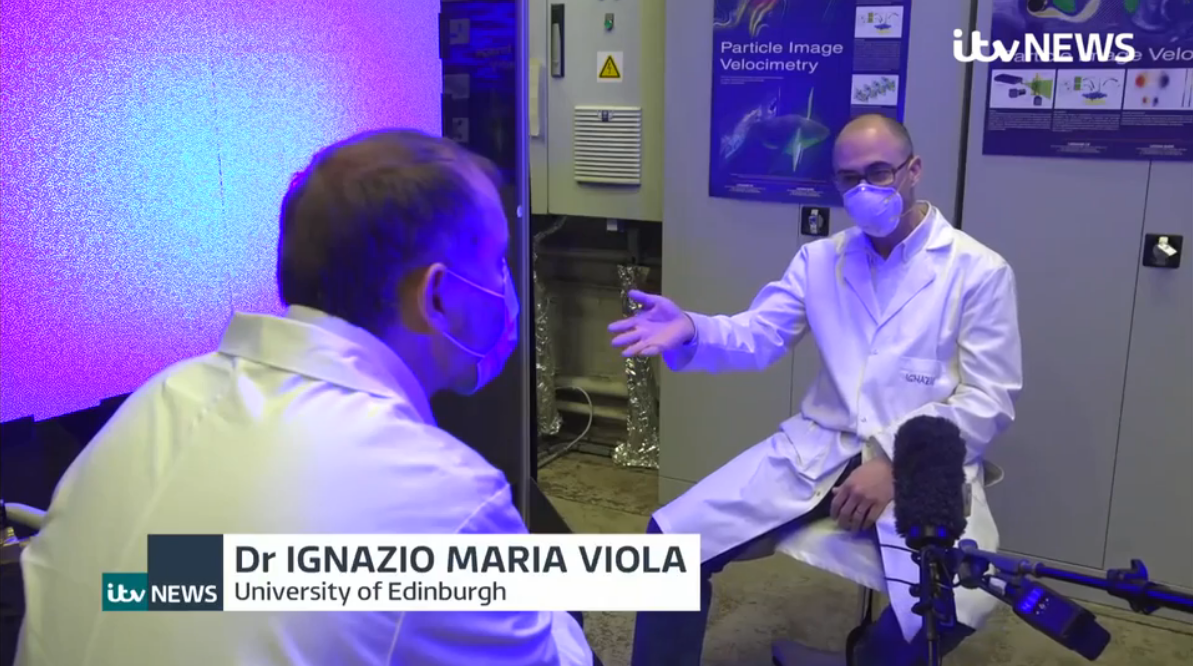

The research was referenced in the UK Government’s SAGE Committee documents which underpinned policy on face masks. Principal Investigator, Dr Ignazio Maria Viola, gave several TV and radio interviews explaining the research to media outlets including BBC Breakfast and ITV News (pictured). Read more.

Dr Ignazio Maria Viola explaining the University's research on face coverings on ITV News

Face shields for frontline workers

The Covid-19 pandemic created an unprecedented demand for face shields to protect key workers. Staff and students from the School of Engineering were among those who responded to the call.

Led by Dr Katherine Dunn, the group initially turned to 3D printing (3DP) to produce face shield headbands, but soon also discovered a quick laser cutting method to create full face shields from sheet plastic. The laser-cut shields took around 70 seconds to produce and were believed to be re-usable, unlike their 3DP counterparts.

The project involved PhD students, researchers, technicians, support staff and academics from across the University. Ultimately the team made and donated nearly 12,000 3DP and laser-cut shields – mainly to workers in health and social care.

Watch this short video to find out more.

Technician Andrew Brown works on 3D-printed face shields in the mechanical engineering teaching laboratory

Independently, a number of our alumni have also made significant contributions to the face shield production effort, particularly the dynamic team at the innovative tech start-up Augment Bionics. This company was founded by a group of University of Edinburgh students including engineering alumnus George Dzavaryan (2019, BEng Mechanical Engineering with Management).

Back in autumn 2018, the group identified a gap in the market for affordable and functional prosthetic limbs manufactured using 3D printing. When the pandemic struck, the company decided to devote its expertise to the manufacture of face shields. Read more.

Engineering vital parts for intensive care units

The Scottish Microelectronics Centre (SMC), a research facility based in the School of Engineering, has been helping technology companies to manufacture critical parts for use in intensive care units during the Covid-19 pandemic.

The SMC ordinarily works with a range of commercial and academic clients, specialising in MEMS (micro-electromechanical system), semiconductor, and nano fabrication – a range of cutting-edge engineering manufacturing techniques which take place at very small scales in the tightly controlled environment of a cleanroom.

The research facility has been supporting two companies – Druck and Pyreos – to meet the demand for specialist sensors used in ICUs (intensive care units) and the wider community.

Members of staff working in the cleanroom of the Scottish Microelectronics Centre

Pioneering face mask design

In late March, the Scottish Government’s Chief Scientist Office launched the Rapid Research in Covid-19 (RARC-19) funding call, as a key element of its Covid-19 response – calling on Scotland’s research community to propose initiatives to better understand and fight the virus.

Among those funded is a team led by Dr Adam Stokes, which received an £84,000 funding boost to develop 3D customised facemasks that meet or exceed the WHO standard. The masks are currently being tested in a small-scale (66-person) formal clinical trial led by Ken Stewart and Dr Aidan Roche.

Follow the project’s progress.

Disinfectant solutions

Researchers across our School have also been responding to the increased demand for disinfectant and sterilisation solutions to Covid-19.

The company Aqualution Systems approached the University to develop a continuous production process for making a sustainable disinfectant product. The resulting project – led by Dr Faiz Iqbal (Principal Investigator) and Dr Adam Stokes (Co-Investigator) – recently received £51,000 in funding from the EPSRC’s Impact Acceleration Accounts (IAA) scheme.

Remote sterilisation of ambulances

In a separate initiative, a team led by Dr Symon Podilchak (Senior Lecturer in Radio Frequency Technology) have worked on a radio frequency (RF) remote sterilisation technique that could be used to quickly and efficiently clean ambulances, medical devices and other assets, between uses.

While hospital rooms and other settings are currently cleaned manually after use, Dr Podilchak proposes to use an automated and hands-free system based on electromagnetic waves, RF circuits, and antenna arrays to do the job. The new technique promises to save time, increase accuracy, and minimise the exposure of healthcare staff and others to the virus.

This remote sterilization work is in collaboration with Toshiba and Leonardo UK and follows the team's previous industrial research project on the wireless power charging of mobile phones and tablets, supported by Samsung.

Read about the results of this study.

Testing labs in shipping containers

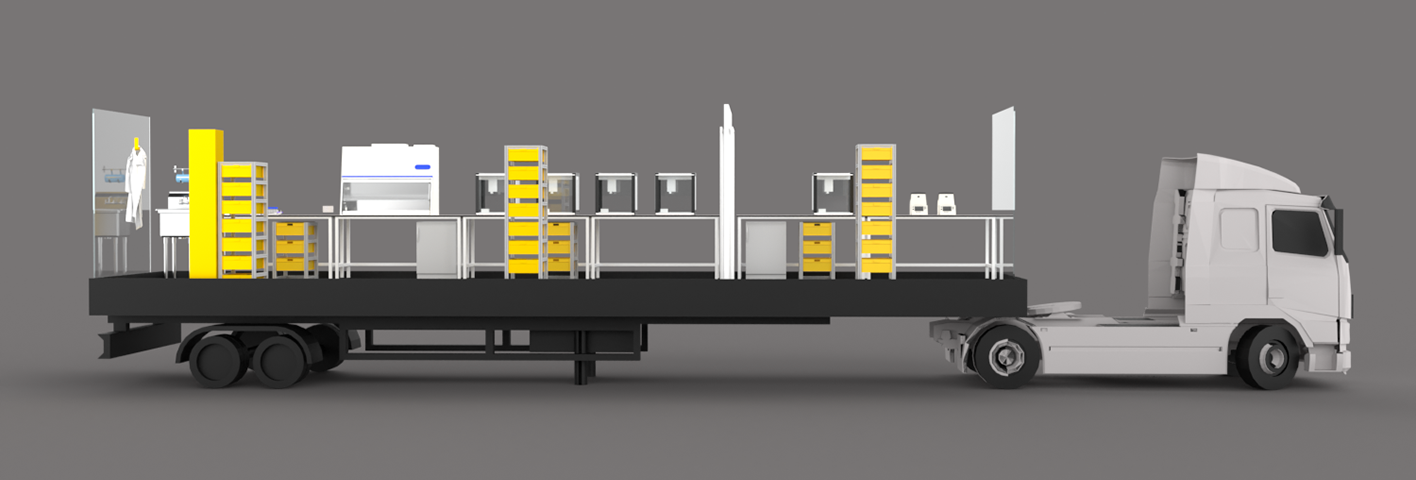

A recent alumnus of the School of Engineering is part of a team of researchers who have developed a low-cost, open-source Covid-19 testing laboratory housed in a shipping container.

Dr Matthew Donora, who recently completed his PhD in smart contact lenses under the supervision of Professor Ian Underwood, is Head of Engineering at OpenCell – a London-based company which makes biotech laboratories in shipping containers.

The team worked with Kings College London to develop the first known example of a fully functional Covid-19 testing lab, as opposed to individual components – that can be instantly deployed anywhere in the world. Read the full story.

Alumnus Dr Matthew Donora has been working on a Covid-19 testing laboratory housed in a shipping container with his company OpenCell (Image credit: OpenCell)

Identifying global health issues

At the beginning of the Covid-19 pandemic, it became clear that poor communities living in high density urban environments across low- and middle-income countries in the Global South would suffer the combined effects of Covid-19 and extreme heat.

Measures such as lockdowns, home quarantines and social distancing looked set to exacerbate already precarious livelihoods by reducing income opportunities and exposing populations to heat stress resulting from inadequate housing and infrastructure.

Responding to a suggestion from the Red Cross Climate Centre, an interdisciplinary research team including the School’s Dr Daniel Friedrich developed a 30-question survey to collect critical information on these vulnerabilities, and the interplay with Covid-19 mitigation measures in Sub Saharan Africa, South Asia and South East Asia.

Over summer they conducted the survey in Karachi, Pakistan; Douala, Cameroon; Jakarta, Indonesia; and Hyderabad, India, and collected over 1100 responses in each of the four cities. They are currently analysing the data to generate vital knowledge, learning and tools.

Find out more about the survey and data sets (which are publicly available) in this blog.

Are you a staff member, student or alumni involved in a significant Covid-19 project that isn’t mentioned here? Please contact news.eng@ed.ac.uk